ALL OF ABORD: Is it FlexSim?

F lexSim is a 3D simulation software designed to model logistics and production systems in all types of industries: production, packaging, warehouses, handling…

lexSim is a 3D simulation software designed to model logistics and production systems in all types of industries: production, packaging, warehouses, handling…

It features a full range of powerful tools such as scale 3D visualization and virtual reality immersion, or dashboards to centralize all the statistical information that informs the system's behavior and performance. It is a decision-making tool but also a powerful training and communication tool.

Some examples of applications: reconfiguration of a production line, deployment of automated storage systems, listing of new activities, implementation design and associated traffic plan…

Some examples of applications: reconfiguration of a production line, deployment of automated storage systems, listing of new activities, implementation design and associated traffic plan…

In this page, I do not go back to the pros and cons of FlexSim as a simulation tool but I only explain how to download, install and use this tool through examples and case studies.

1. Download and install FlexSim Gratruitment

FlexSim simulation software is available in two "Free and Paying" versions.

In the video below I explain all the details how to download and install this tool the free version of 2020.

https://www.youtube.com/watch?v=jbX28kRY4Wo&list=PLLk00LzBzwBcAnfPCK_6awCmoNhDjiDHy

2. Start with FlexSim (Insertion of Objects, 3D View Navigation, Rotation of an Object)

3. Start with FlexSim (select, rename and connect multiple objects)

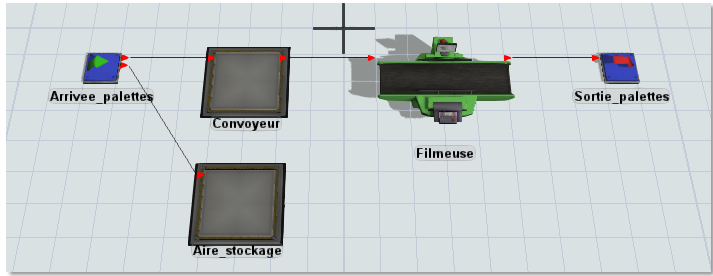

Model 1: Pallet filmer

Starting data:

Objective

'introduce the basic stages of the construction and exploitation of the results of a model

Description

-

the pallet film line runs from 9:00 a.m. to 5:00 p.m. without interruption

-

pallets arrive at minimum intervals of 10s, and 1 minute on average. The law of arrival of pallets follows an exponential distribution.

-

the conveyor belt upstream of the filmer has a maximum capacity of 10 pallets

-

If a pallet arrives when the conveyor is full, it is set aside

-

The filming time of a pallet is 55 seconds

Questions

-

What is the average waiting time for pallets on the conveyor?

-

What is the filmer's occupancy rate?

-

How many pallets had to be set aside?

In the video below I explain in detail the correction of this first model to arrive at the solution below:

Correction Model 1 Part 1: The Model's FlexSim Model

https://youtu.be/VNsu2v4eObg

Download the FlexSIM file from this part (Part 1) by clicking on the icon below

Fixed Model 1 Part 2: The FlexSim model with EdgeBoard

https://youtu.be/Nqc82OjueVc

Download the FlexSIM file from this part (Part 2) by clicking on the icon below

Fixed Model 1 Part 3: The FlexSim model with 3D formats

Download the 3D format of the filmer and the Coke palette by clicking on the icons below:

| 3D format of the Coca palette |

3D format of the filmer |

|

|

https://youtu.be/bs76ot52pSg

Download the FlexSIM file from this part (Part 3) by clicking on the icon below

Model 1 Part 4 Correction: Test several scenarios

https://youtu.be/J3a0pwdO0_k

Download the FlexSIM file from this part (Part 4) by clicking on the icon below

Model 2: Production and control workshop for 4 different parts

Start data:

-

Objective

'introduce the basic stages of the construction and exploitation of the results of a model

-

Description

'the pallet filming line runs from 9:00 to 17:00 without interruption

'pallets arrive at minimum intervals of 10s, and 1 minute on average. The law of arrival of pallets follows an exponential distribution.

'the conveyor upstream of the filmer has a maximum capacity of 10 pallets

"If a pallet arrives while the conveyor is full, it is set aside

'the filming time of a pallet is 55 seconds

-

Questions

"What is the average waiting time for pallets on the conveyor?

"What is the filmer's occupancy rate?

"How many pallets had to be set aside?

Fixed Model 2 Part 1: Solution without retouching parts

https://youtu.be/O2V2qcAEoAU

Download the FlexSIM file from this part (Part 1) by clicking on the icon below

Correction Model 2 Part 2: Solution treatment of defective parts

https://youtu.be/boaPhn_NxTc